Downloads

BROCHURE

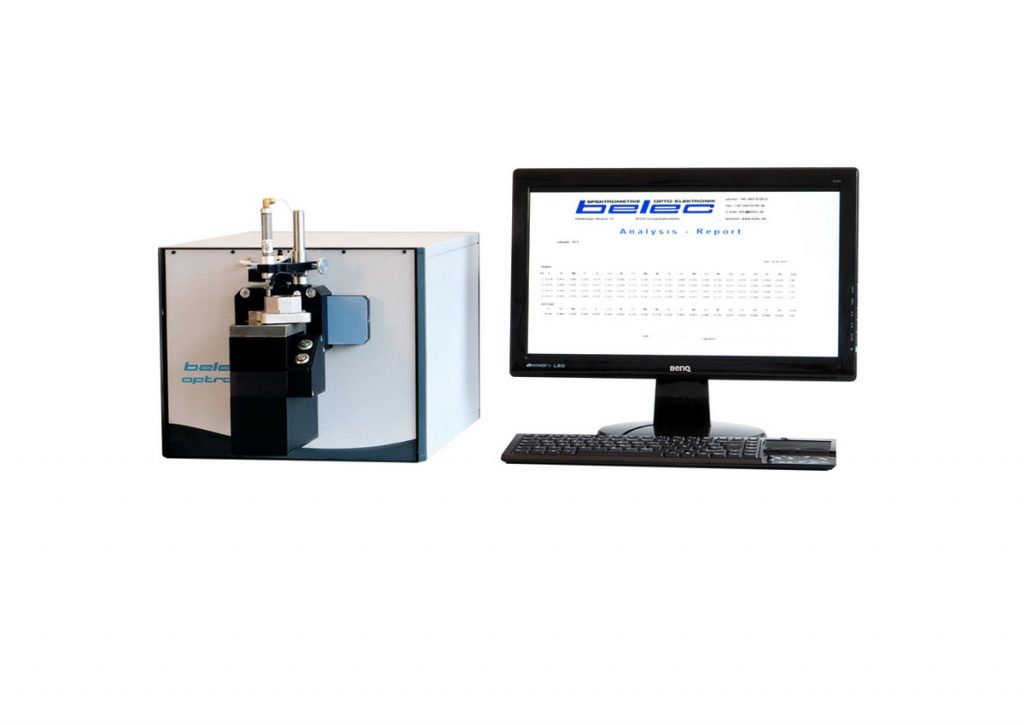

Belec OPTRON – The new class for your metal analysis

SIMPLICITY MEETS EFFICIENCY

Belec again raises the standards with a new compact metal analyser. The all new model Belec OPTRON guarantees an unbeaten performance using the unique double spectrometer design. It is used in the traditional foundry business as well as in incoming inspection or the recycling industry. Any metal processing company can take advantage of the very attractive price to performance ratio.

The Belec OPTRON is a true all-rounder: There are virtually no limitations as far the numbers of analytical programs is concerned, even with its small footprint the Belec OPTRON will surprise you with neat accuracy and precision. Be it a single- or multi-base operation, the Belec OPTRON is your ideal companion for your quality assurance. By using pre-set and easy selectable operator functions like standard analysis, type corrected measurement or grade check, it guarantees the fulfillment of all the requirements of modern metal analysis. The integrated dynamic grade database is standard like in all other Belec spectrometers as well. With any analysis the software identifies the according grade name, be it according to German, European, USA or any other international norms. It can be extended without limitations and of course customized to your own specifications.

Romquest Technologies is the exclusive Canadian distributor for reputable manufacturers of high quality analyzers and consumables from Europe and USA. Our product lines include: Eltra Elemental Analyzers, Eurovector CHNS/O and N-Protein Analyzers, Belec Optical Emission Spectrometers, Rigaku Handheld LIBS Analyzers, Radwag Balances & Scales and Alpha Resources consumables, supplies and certified standards for elemental analyzers/ICP/AA/MS.