Downloads

BROCHURE

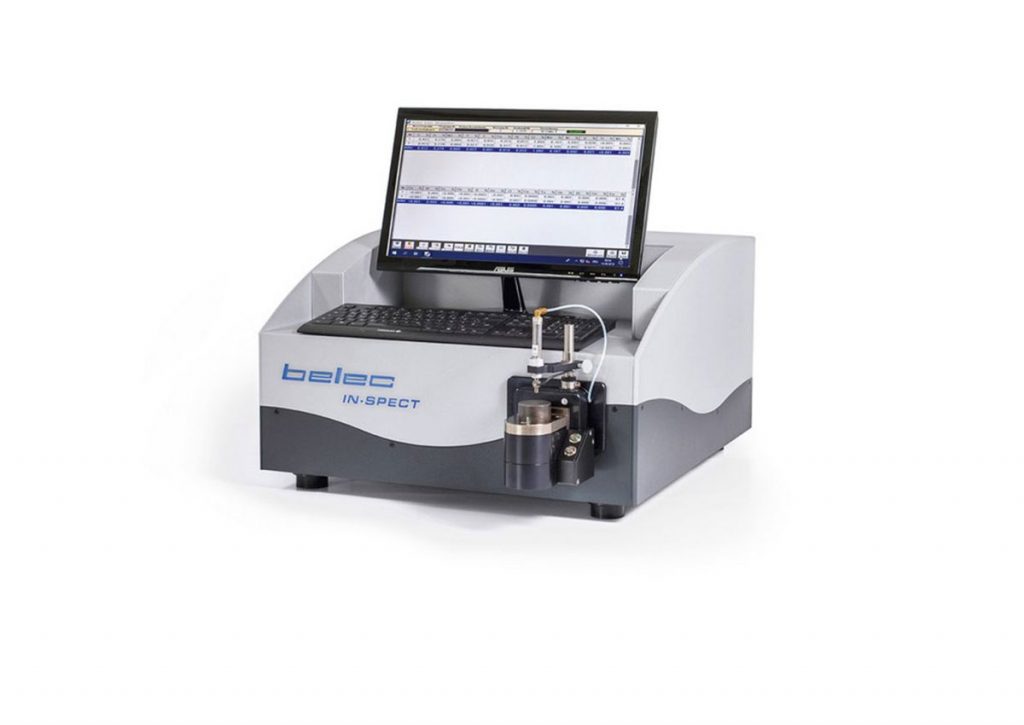

MAXIMUM. COMPACT.

With the completely redesigned metal analyzer Belec again sets new standards. The all new Belec IN-SPECT with its unique dual-spectrometer optics guarantees unbeaten performance in conjunction with significantly reduced maintenance costs in this instrumentation class.

It is used in the classic smelting control in foundries as well as in goods receiving, recycling or in regular quality assurance for production control.

The Belec IN-SPECT is a true multifunctional wonder:

Almost unlimited in the number of measuring programs, it fulfills almost every requirement combined with extremely attractive pricing.

Romquest Technologies is the exclusive Canadian distributor for reputable manufacturers of high quality analyzers and consumables from Europe and USA. Our product lines include: Eltra Elemental Analyzers, Eurovector CHNS/O and N-Protein Analyzers, Belec Optical Emission Spectrometers, Rigaku Handheld LIBS Analyzers, Radwag Balances & Scales and Alpha Resources consumables, supplies and certified standards for elemental analyzers/ICP/AA/MS.